Top Choices Only

Three Filaments. Infinite Possibilities.

PETG combines excellent durability, impact resistance, and chemical resistance with moderate heat tolerance. It’s a versatile material that works across a wide range of applications, making it the go-to option for general-purpose parts.

ASA offers superior heat resistance and specific strength compared to PETG, making it a robust choice for higher-demand applications. It is also UV-stable, enabling long-term outdoor use without degradation.

20% CF Filled Variants

The addition of 20% carbon fiber to PETG and ASA enhances their inherent strengths, creating materials that excel in toughness, stability, and performance.

Carbon fiber increases stiffness and tensile strength, improves dimensional stability for complex or large parts, minimizes warping and shrinkage during printing, and reduces part weight while maintaining structural integrity.

For PETG

- Enhances impact resistance and reduces tendency to flex under load

- Ideal for durable, precise functional parts

- Increases Heat Deflection Temperature (HDT) for higher temperature endurance

For ASA

- Boosts it’s natural impact resistance, rigidity, and thermal stability

- Suitable for strong, durable parts in challenging environments

- Reduces warping and shrinkage, ensuring reliability for large or intricate designs

- Increases HDT for better performance in high temperatures

Common Benefits

Both PETG and ASA carbon fiber-filled plastics offer significant visual advantages, featuring a rich matte finish that effectively hides layer lines and a deep, uniform high-end appearance in almost any light conditions.

Furthermore, the CF present in the material gives the parts a very deep uniform color that looks very high end and allows for great visuals.

This enhances their visual appeal for products handled by customers, making them superior to non-filled plastics in terms of aesthetics.

Downsides

These benefits come with a few downsides, including ~ double the cost per kilogram compared to non-filled plastics and the potential abrasiveness of carbon fiber, which may cause issues in systems with repeatedly contacting moving parts.

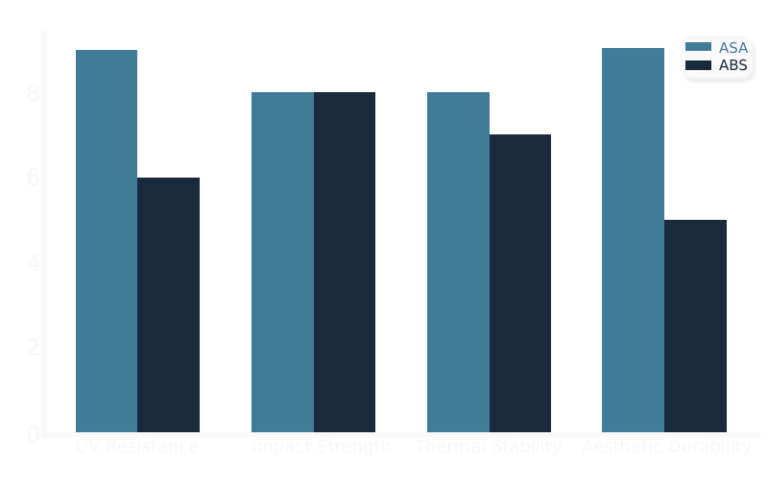

Why We Don’t Carry ABS

ASA in not just an alternative to ABS but the evolution of ABS.

It builds upon ABS’s strengths—like durability, impact resistance, and versatility—while resolving its weaknesses, such as UV vulnerability and warping during printing.

By carrying ASA, we eliminate complexity and confusion while delivering the highest quality and reliability for every project.

The Difference

ASA eliminates the need for ABS in nearly all cases through:

- Better tolerances with reduced warping and shrinkage

- Better suitability for high-heat and outdoor environments

- Similar pricing, offering a better value for the same cost

By focusing on ASA, we can guarantee superior results for every use case associated with ABS,

while providing the enhanced capabilities that ABS cannot match.

Why We Focus on These Materials

Manufacturing your designs doesn’t have to be complicated!

Most cases never justify using more than one type of plastic, and even in those cases our plastics selection will cover 99% of them.

By trimming down the variety of potential plastics, it allows us to provide the best user experience overall, because printing isn’t just about those edge case scenarios, it’s about the meat and potatoes of manufacturing your products.

Versatility

Our materials cover the spectrum of needs, from consumer-grade products to high-end industrial parts.

Consistency

Fine-tuned offerings mean our printers are finely tuned to these materials, ensuring optimal results every time.

Sustainability

By focusing on a few materials, we reduce waste and maintain an efficient supply chain.

Turnaround

We can streamline operations, allowing us to get products to you lightning fast, every time.

Versatility

Each material we offer is chosen for its ability to deliver excellent performance at a competitive price.

Don't worry!

We also recognize there may be cases where our customers need a specific plastic and we don’t offer it. Don’t worry, it doesn’t mean our machines aren’t capable of printing with these plastics at the highest levels of precision. In specific cases we can happily negotiate specific contracts to provide those services.