Our Proprietary Printers

Outprinting Limits. Outperforming Expectations.

Freedom to Create, Precision to Deliver.

Achieve complex geometries with tolerances validated across hundreds of tests.

CoreXY, Perfected

The Future of Motion Control

AI enhanced look-ahead algorithms for perfect curves and complex geometries

Fast and Flawless

Advanced kinematics enable extreme speeds, maintaining smooth, accurate results.

Thermal Regulation

Thermally managed chamber for max. layer adhesion and minimal dimensional warping.

Fully Automated

Zero downtime via automated part retrieval (ASRS) & other automated processes.

Remarkably Precise

Achieving tolerances of +/- 0.10% for even the most intricate & custom models.

AI-Driven Accuracy

Hundreds of machine parameters fine-tuned by AI

for highly detailed precision.

Node in a Network

Each machine is integrated in our proprietary manufacturing execution system (MES)

Modular Design

Modular setups & upgrades keep you at the forefront of

3D printing technology.

Flow Meets Motion

Advanced algorithms ensure precision extrusion & dynamic motion for high-end prints.

Innovation in Every Layer

Our machines are the most advanced platform for scalable FDM 3D printing, revolutionizing design and manufacturing.

Every aspect embodies cutting-edge engineering, built with modularity and the future in mind. Constantly evolving, our machines improve as we discover new ways to enhance 3D printing – Cutting edge is just the beginning.

Whether it’s intricate geometries to production-grade components, this is the future of 3D printing—unlocked.

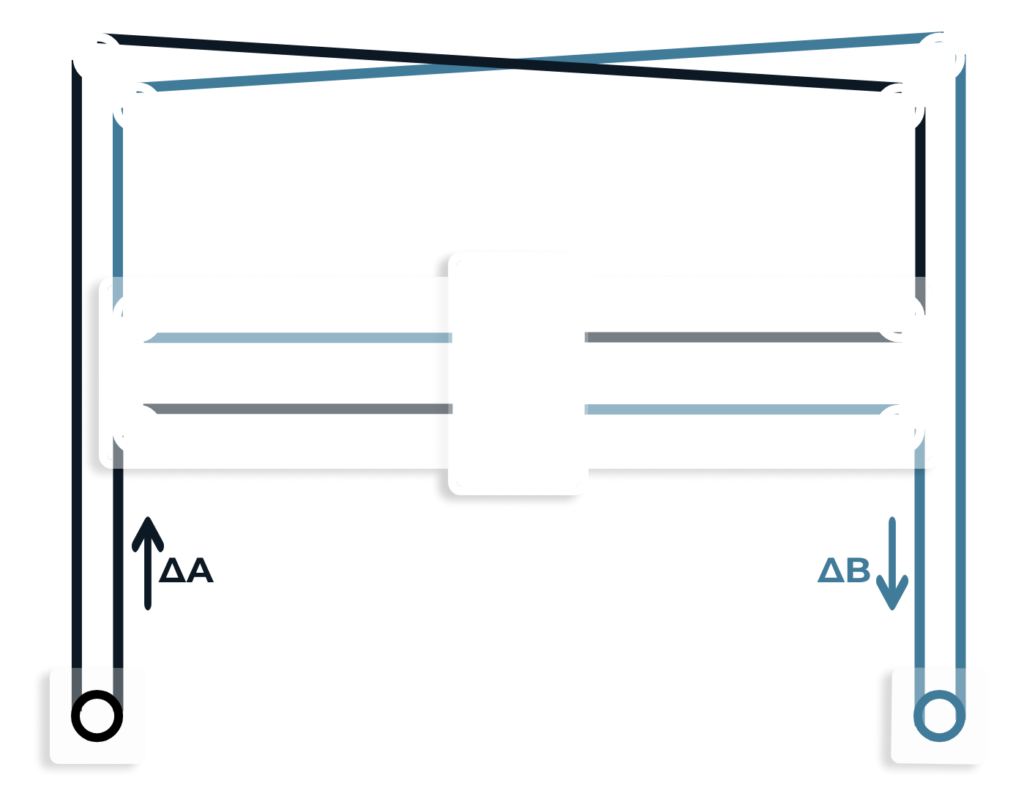

CoreXY Kinematics - Fast and Elegant

Engineered for speed and stability, CoreXY kinematics is the ideal foundation for motion control.

This advanced system minimizes inertia and maximizes efficiency, enabling ultra-smooth, high-speed movement without compromising on accuracy.

The synchronization of the X and Y axis reduces mechanical errors and increases motion precision.

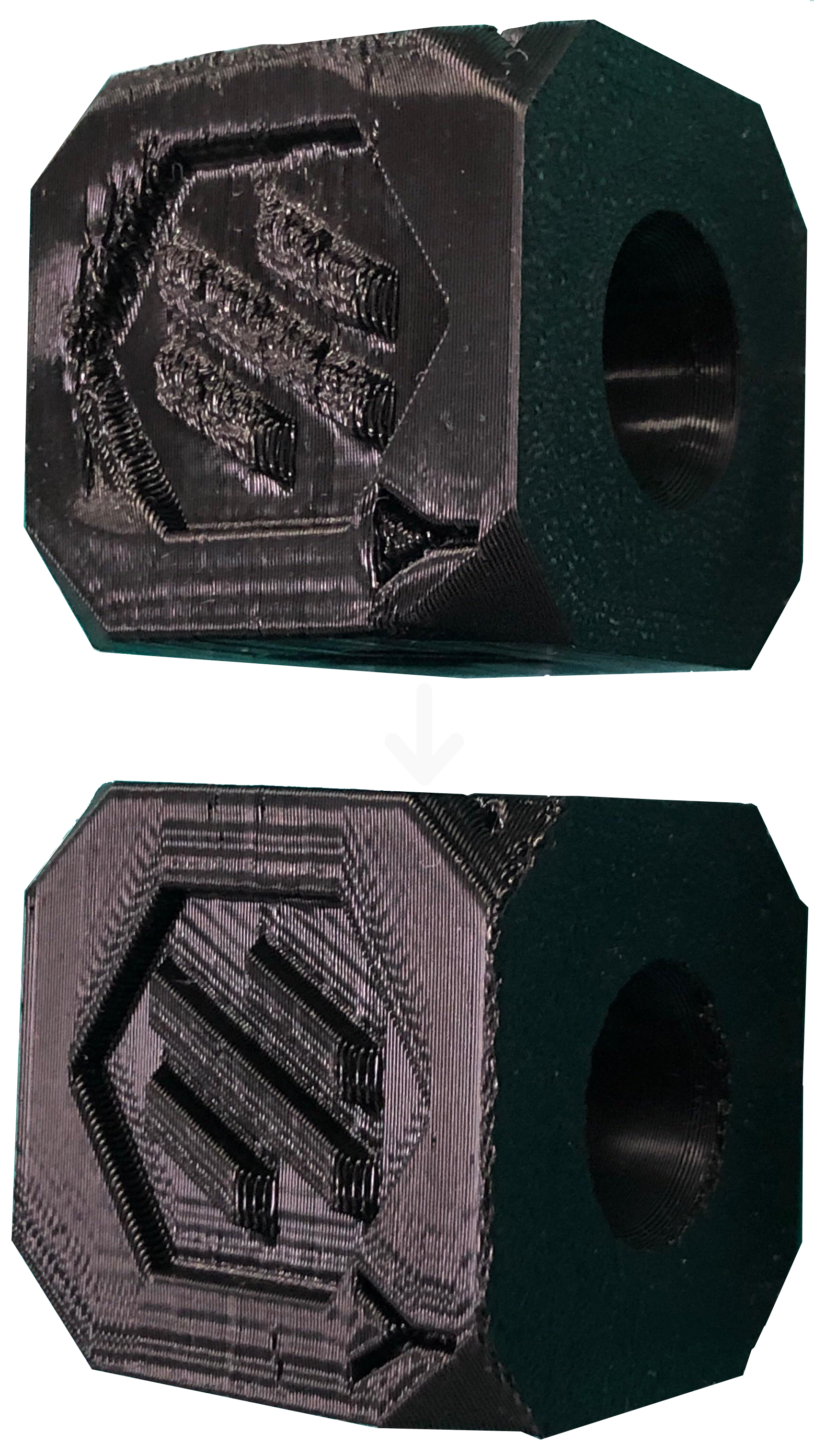

High Precision through Input Shaping Technology

Input shaping is a sophisticated open-loop control technique that preemptively counteracts vibrational artifacts caused by rapid accelerations and decelerations in motion systems.

By mathematically compensating for resonance frequencies, this technology allows for higher speeds, sharper corners, and cleaner finishes—without the need for feedback loops.

Integrated into our advanced motion control system, input shaping ensures optimized trajectories, maintaining dimensional accuracy and smooth transitions even at extreme velocities. This is engineering precision, elevated.

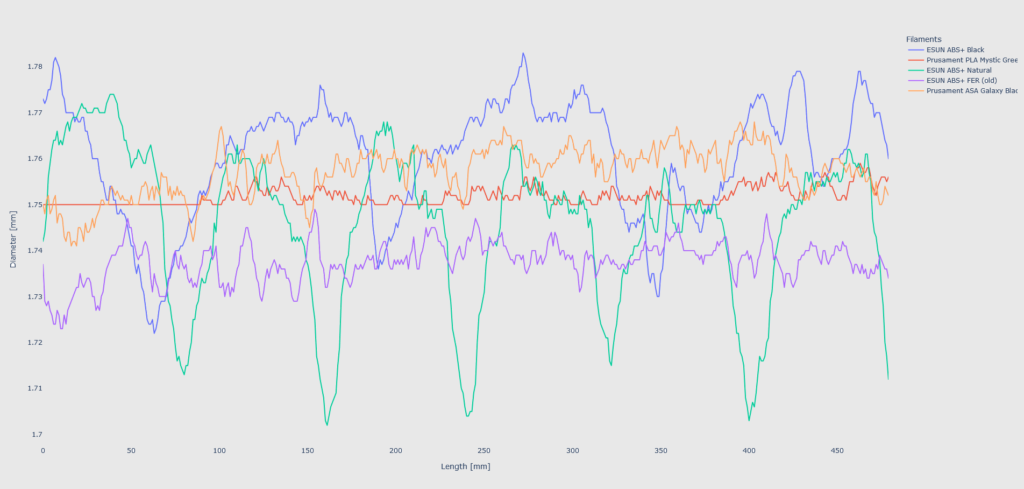

Real-Time Filament Monitoring

Filament analysis and compensation technology ensures every part is crafted to exacting standards.

By monitoring and adjusting for filament diameter variations in real time, our system delivers uniform extrusion and eliminates weak points.

All data is logged and available in your Printfolio, offering complete transparency into material performance and quality control.

The result?

Parts you can trust to perform as designed, even in the most demanding applications.

AI-Optimized Performance

Our system is meticulously fine-tuned across hundreds of parameters, guided by advanced AI and industry expertise, to operate as close to the idealized potential of today’s materials and technology as possible.

By extracting maximum performance from every variable, we deliver parts of unparalleled quality, setting a new benchmark for what can be accomplished in additive manufacturing.